2016-08-02

Designed for once-in-a-century events

RINGSPANN appearing in Hamburg as partner for wind power technology

At the end of September, component and system manufacturer RINGSPANN will be presenting its technical solutions for engineering and plant construction companies in the wind power sector at the WindEnergy Hamburg. As well as new heavy-duty friction torque limiters for overload protection and large shrink discs for the external clamping of hollow shafts, energy-efficient industrial brakes and the brake control system BCS 600 will be taking centre stage at the trade fair. RINGSPANN will be in hall B7 at stand 225.

Bad Homburg, August 2016. – Critical overload situations, once-in-a-century meteorological events and sudden emergency stops – modern wind power plants have to be prepared for such extreme cases. Their development and design engineering therefore follows special rules and strict criteria. Component and system manufacturer RINGSPANN will also have these exceptional requirements in mind when presenting its heavy-duty friction torque limiters, shrink discs and high-performance brakes to the professional visitors of WindEnergy Hamburg from 27th to 30th September 2016.

Efficient brake systems

The wide and diverse RINGSPANN range of hydraulic, pneumatic and electromagnetic industrial brakes, which can be used as control, holding and emergency stop systems, are sure to arouse the interest of many wind power engineers, especially since RINGSPANN only recently extended its range to include electrical disc brakes with clamping forces of up to 24 kN. These new electromagnetic industrial brakes of the series EV and EH are low-maintenance and score brownie points for their compact installation dimensions, small weight and high functionality. They also impress by the fact that they make do with a minimal power consumption over the entire retention phase; just 10 Watts with the small sizes. Meaning the new RINGSPANN brakes set standards internationally and help with the realization of energy-efficient wind power plants.

There are further maintenance-related advantages resulting from the fact that the braking torque (clamping force) can be adapted easily and very accurately to the case of application using an adjusting nut, and that exchanging worn friction blocks can also be done in a few simple steps – without the need to disassemble the brake! The sensor monitoring of the brake function and degree of brake lining wear are further features that make maintenance and handling easier. All sensor-related monitoring functions can be integrated into higher-level safety and control systems of wind power plants.

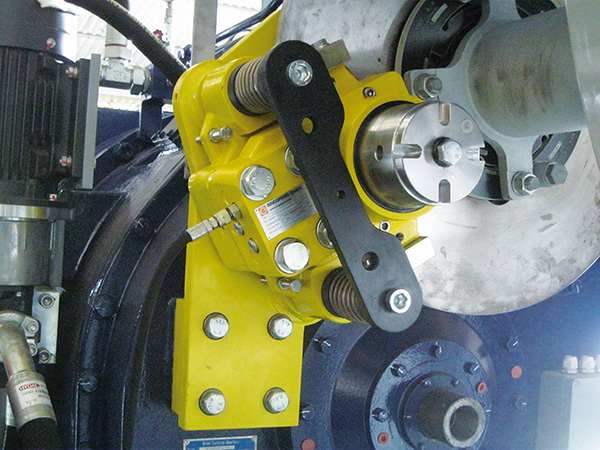

As an alternative to the electrical brakes, RINGSPANN offers numerous series with pneumatic and hydraulic brakes. The following stand out here among others: the brake calipers HS 120 FHM (spring-activated/hydraulically released) or the hydraulically activated and non-releasing HI 180 HUK, which are used as azimuth brakes in wind power plants for example. It is also of central importance for use in wind force technology that RINGSPANN offers the brake control system BCS 600 for all its hydraulically activated and hydraulically released brakes. This intelligent control system performs not only complex braking processes (time, distance,deceleration), but also assumes important safety and monitoring functions. It consists of an electronic control and regulation unit with controller, I/O system, web interface and touchscreen as well as a complete hydraulic aggregate. The BCS 600 also controls and monitors several brake systems at the same time, can be remote-maintained via the internet (optional) and can be integrated into higher-level infrastructures via EtherCat, Profibus or CANopen.

Overload protection for extreme cases

A further trade fair highlight, RINGSPANN will be presenting its new high-performance friction torque limiter RSHD at the WindEnergy Hamburg. This torque limiter, which is fitted with first-class components and designed in line with the RIMOSTAT® principle, is able to keep even the highest slipping torques of up to 60,000 Nm constant over a very long operating time with minimum wear. It also stands out for its high dry running stability at very high temperatures in the area of the friction linings. Plant construction companies from the wind power technology sector therefore get premium-class overload protection, allowing them to lower the risk of damage and failure of their drive units and minimise maintenance work.

Worth mentioning: With the RIMOSTAT® friction torque limiters from RINGSPANN, it is not Belleville springs but long ISO coil springs that, with a linear and flat curve progression, produce a contact pressure on the friction linings. Even if there is wear to the friction lining, the decrease in the slipping torque (the crucial performance parameter of a friction torque limiter) is therefore hardly worth mentioning. Since RINGSPANN developers have also fitted the new overload protection with high-performance friction linings made of nickel-free sintered material, they have managed to exploit these design advantages far into the upper heavy-duty range.

RINGSPANN offers the new heavy-duty friction torque limiter in five different sizes for use in wind power technology. The smallest RIMOSTAT® RSHD has a diameter of 205 mm and covers slipping torques from 300 to 3000 Nm at speeds of up to 2,700 min-1. The largest version has a diameter of 600 mm and can be used for slipping torques from 20,000 to 60,000 Nm at speeds of up to 1000 min-1. With all sizes, there is the possibility of setting the slipping torque to meet the requirement. Practical: This is not done by adjusting the pre-stress of each individual spring, but by activating or deactivating complete springs. On request, RINGSPANN will factory-set the slipping torque.

Reliable clamping of large shafts

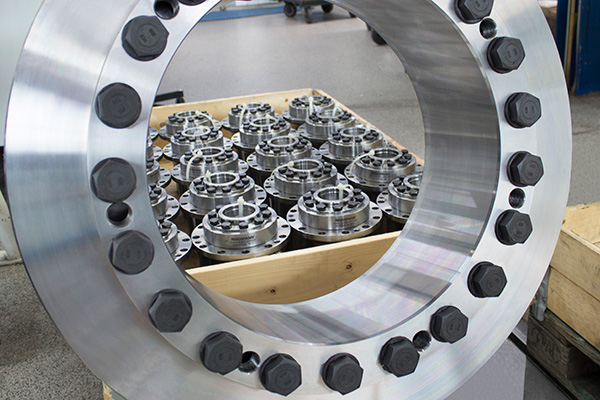

The third main WindEnergy focus at the RINGSPANN stand 225 in hall B7 will be the shaft-hub-connections product group – and above all the new shrink discs of the series RLK 608 and RLK 603 for the external clamping of hollow shafts with large diameters. With a keen eye for applications in wind power technology, RINGSPANN has extended these series to include two and three-part shrink discs for powerful shafts with diameters of up to 620 mm and 500 mm. These shrink discs can transfer incredible torques of up to 4,225,000 Nm (RLK 608) or 1,460,000 Nm (RLK 603) and are suitable for the backlash free connection of hollow shaft gearboxes with machine shafts or of cardan shaft flanges with drive shafts.

The executions of the series RLK 608 are modern two-part shrink discs (one stepped conical ring/one stepped conical bushing), which, thanks to their closed construction, are insensitive to dirt and also ensure wobble-free running at high speeds. They can easily be assembled using clamping screws in a distance-controlled manner and without a torque wrench. The RLK 603 shrink discs on the other hand follow the classic three-part setup (two stepped conical rings/one stepped conical bushing) and are mounted by means of a torque wrench. Both series make the simultaneous transmission of torques and axial forces possible and centre the hollow shaft or hub to the shaft.

The recent 2016/17 catalogue now provides a complete overview of the current RINGSPANN portfolio of two and three-part shrink discs, cone clamping elements as well as star discs, special torque motor clamping systems and star spring washers for ball bearing compensation.

Whether high-performance brakes, friction torque limiters or shaft-hub-connections – RINGSPANN provides design engineers and developers from the wind power industry with excellently processed quality solutions in all three product groups, which help with the realisation of economical, safe and low-maintenance onshore and offshore installations.